The agricultural sector is undergoing a rapid transformation. Driven by the need for increased efficiency, precision, and sustainability, farmers are increasingly adopting advanced machinery. At the heart of many of these innovations lies a critical component: the gear motor. Often unseen but undeniably vital, gear motors are power transmission devices that bridge the gap between electrical energy and mechanical motion, enabling the sophisticated operations required in modern farming. This article explores the crucial role of gear motors in agricultural machinery, highlighting their functionalities, benefits, and future potential, particularly in the context of the current push for precision agriculture and automation.

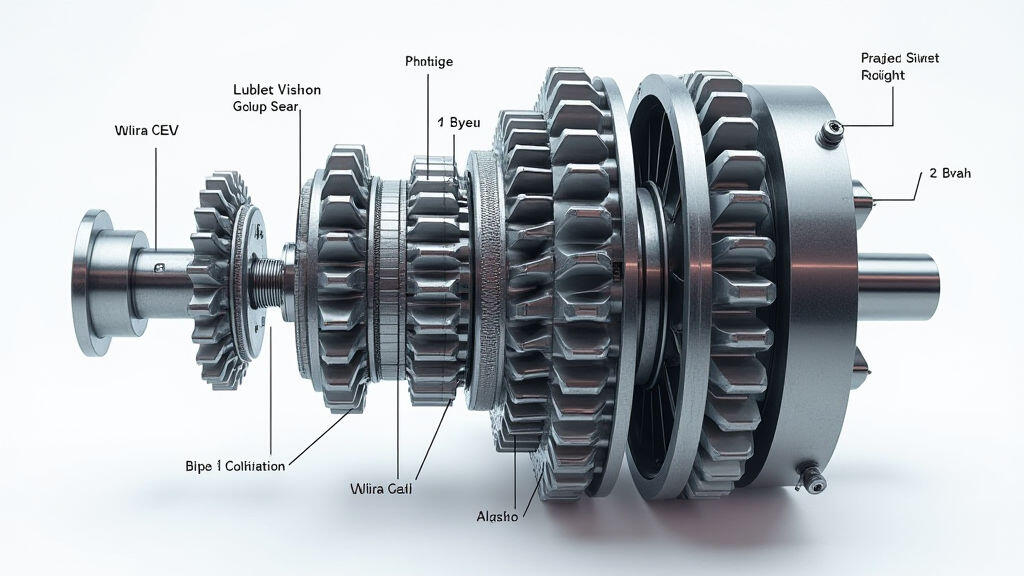

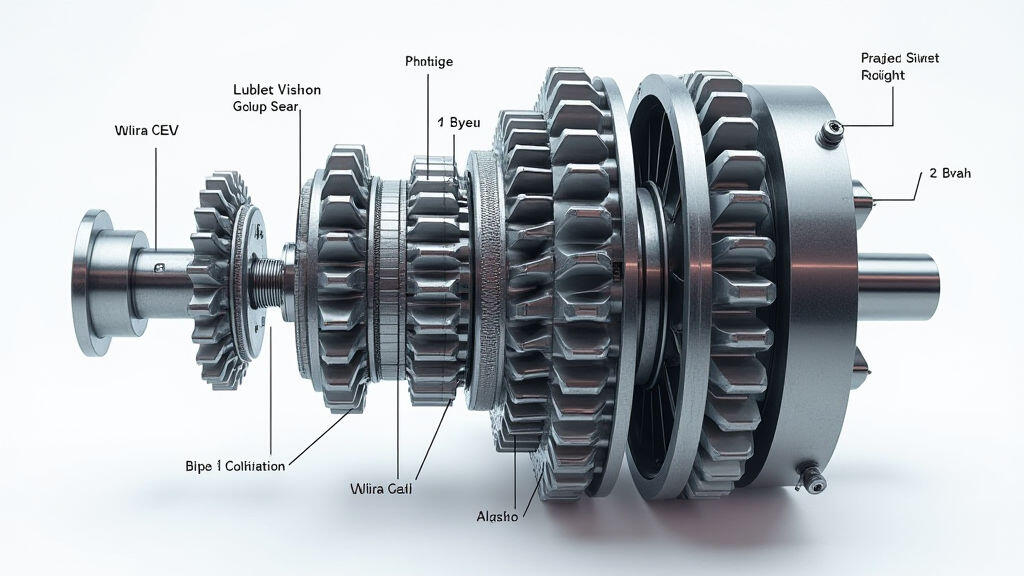

A gear motor combines an electric motor with a gearbox. The electric motor provides the rotational power, while the gearbox modifies the speed and torque output. This combination is particularly advantageous in agricultural applications because it allows for the generation of high torque at lower speeds, which is essential for tasks like tilling, harvesting, and spraying.

The gearbox, comprising several gears of varying sizes, works by changing the rotational speed and torque. Higher gear ratios result in lower output speeds but significantly increased torque. This is crucial for overcoming the resistance encountered during demanding agricultural tasks, such as working with dense soil or heavy crops. There are different types of gear motors, including planetary gear motors, helical gear motors, and worm gear motors, each offering specific advantages in terms of efficiency, size, and cost.

The versatility of gear motors makes them indispensable in a wide array of agricultural machines. Here’s a closer look at some key applications:

Tractors: Modern tractors rely heavily on gear motors for various functions. They power hydraulic pumps that control implements like plows, cultivators, and sprayers. Gear motors also drive auxiliary equipment such as PTO (Power Take-Off) shafts, powering mowers, balers, and other attachments. The precise control offered by gear motors is vital for consistent and efficient field operations. The rise of autonomous tractors is further increasing the demand for reliable and efficient gear motor solutions.

Harvesters: Combine harvesters, used for harvesting grains, require powerful and precise mechanisms for cutting, threshing, and separating crops. Gear motors are integral to controlling these processes, driving rotating components, and ensuring optimal harvesting yields. The increasing complexity of harvester designs, incorporating advanced sensors and automated systems, creates a growing need for compact and robust gear motors.

Sprayers and Fertilizers: Precision agriculture is driving the adoption of variable rate application technologies. Sprayers and fertilizer applicators use gear motors to control the flow of liquids, ensuring accurate and targeted application based on real-time data. This reduces waste, minimizes environmental impact, and optimizes crop yields. The integration of GPS and sensor technology further enhances the precision of these systems, placing a premium on the reliability of the gear motors.

Irrigation Systems: Automated irrigation systems rely on gear motors to control pumps and valves that deliver water to crops. These systems can adjust watering schedules based on soil moisture levels and weather conditions, optimizing water usage and promoting healthy plant growth. The growing concern over water scarcity is driving the adoption of efficient irrigation techniques, boosting the demand for gear motors in this sector.

Milking Machines: Automated milking systems depend on precisely controlled rotational speeds, provided by gear motors, to ensure efficient and gentle milk extraction. Reliable and hygienic operation of these systems is crucial for both animal welfare and milk quality. Increased automation in dairy farming translates directly into a greater requirement for robust and dependable gear motors.

Gear motors offer several distinct advantages over alternative power transmission methods, making them the preferred choice for many agricultural applications:

The future of agricultural machinery is inextricably linked to precision agriculture and automation. Farmers are increasingly leveraging data analytics, sensors, and autonomous systems to optimize crop yields and resource utilization. This trend is creating significant opportunities for innovation in gear motor technology.

One key area of development is the integration of smart gear motors equipped with sensors and communication capabilities. These smart gear motors can monitor their own performance, providing real-time data on torque, speed, and temperature. This information can be used for predictive maintenance, preventing breakdowns and maximizing uptime. Furthermore, these gear motors can communicate with other components in the machine, enabling coordinated operation and improved efficiency.

Another important trend is the development of more energy-efficient gear motors. With increasing concerns about climate change and energy costs, there is a growing demand for gear motors that minimize energy consumption. This is driving innovation in gearbox design and motor technology.

The surge in drone technology for crop monitoring and spraying also benefits from compact, efficient, and reliable gear motors in the drones themselves.

MES-Drive is at the forefront of gear motor technology, providing innovative solutions for the agricultural sector. Our gear motors are engineered for durability, efficiency, and precision, meeting the evolving needs of modern farmers. We’re committed to developing smart gear motor solutions that support precision agriculture and automation, enabling farmers to optimize their operations and maximize yields. Our designs prioritize long-term reliability, minimizing downtime and maximizing return on investment. MES-Drive is not just a supplier; we are a partner in agricultural progress.

Gear motors are the unsung heroes of modern agricultural machinery, playing a crucial role in enabling efficient, precise, and sustainable farming practices. As the agricultural sector continues to evolve towards precision agriculture and automation, the demand for reliable, high-performance gear motors will only increase. Innovation in this field is focused on increasing efficiency, integrating smart features, and enhancing durability. Companies like MES-Drive are leading the charge, developing cutting-edge gear motor solutions that are powering the future of agriculture. The ongoing trends in data-driven farming and autonomous operation solidify the pivotal position of gear motors, positioning them as a cornerstone of agricultural innovation for decades to come.

Leave A Reply

Your email address will not be published. Required fiels are marked